SPECTRO ANALYSIS AND METAL DETECTION

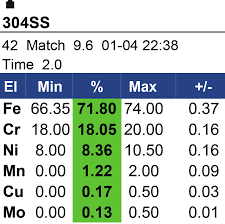

Cast Steel Products utilizes the latest in technology for analyzing metallurgy of parts using non-destructive testing. CSP’s portable spectrometers allow for in-field scans of parts and equipment to provide accurate metallurgical readouts that are uploaded into our database of over 10,000 different metallurgical standards. By determining the metallurgy, hardness, mechanical and tensile strength CSP is able to provide recommendations for improved performance or confirm the current metallurgy of your equipment. CSP utilizes spectro analysis and metallurgical testing to identify unmarked pure and common metals quickly and easily, all while leaving the original part in complete, re-usable condition.

Cast Steel Products metallurgical engineers, with over 50 years of experience, can make precise recommendations for metallurgy, heat treatment, quenching and product design to ensure the desired hardness, elongation, tensile and yield strength are reached. The Spectrometer gives CSP sales representatives instantaneous readouts of scans done in field or in shop. We utilize the information that the spectro analysis gives to create an exact replica part with the same materials, density, and strength that will fit perfectly to the equipment.

Spectrometers are calibrated weekly using base metals to ensure accurate readouts. CSP utilizes Optical emission spectrometers (OES or spark discharge spectrometers), to evaluate metals to determine the chemical composition with very high accuracy. A spark is applied through a high voltage on the surface, which vaporizes particles into a plasma. The particles and ions contained in the atomic vapor are excited into emission of radiation. The radiation emitted is passed to the spectrometer (arc spark OES) optics via an optical fiber, where it is dispersed into its spectral components. The radiation intensity, which is proportional to the element’s concentration in the sample, is recalculated internally from a stored set of calibration curves and can be shown directly as percent concentration.

When in the field, CSP uses portable spectro analysis tools to identify metallurgy, hardness, mechanical, and tensile strength to take the findings and create a replica in the CSP shop that fits the specifications of the equipment exactly. This eliminates any downtime that could occur waiting for a replacement part that may or may not fit. It eliminates the guesswork of the project to quickly ensure continued work. This is an option when the part cannot be moved from its original location.