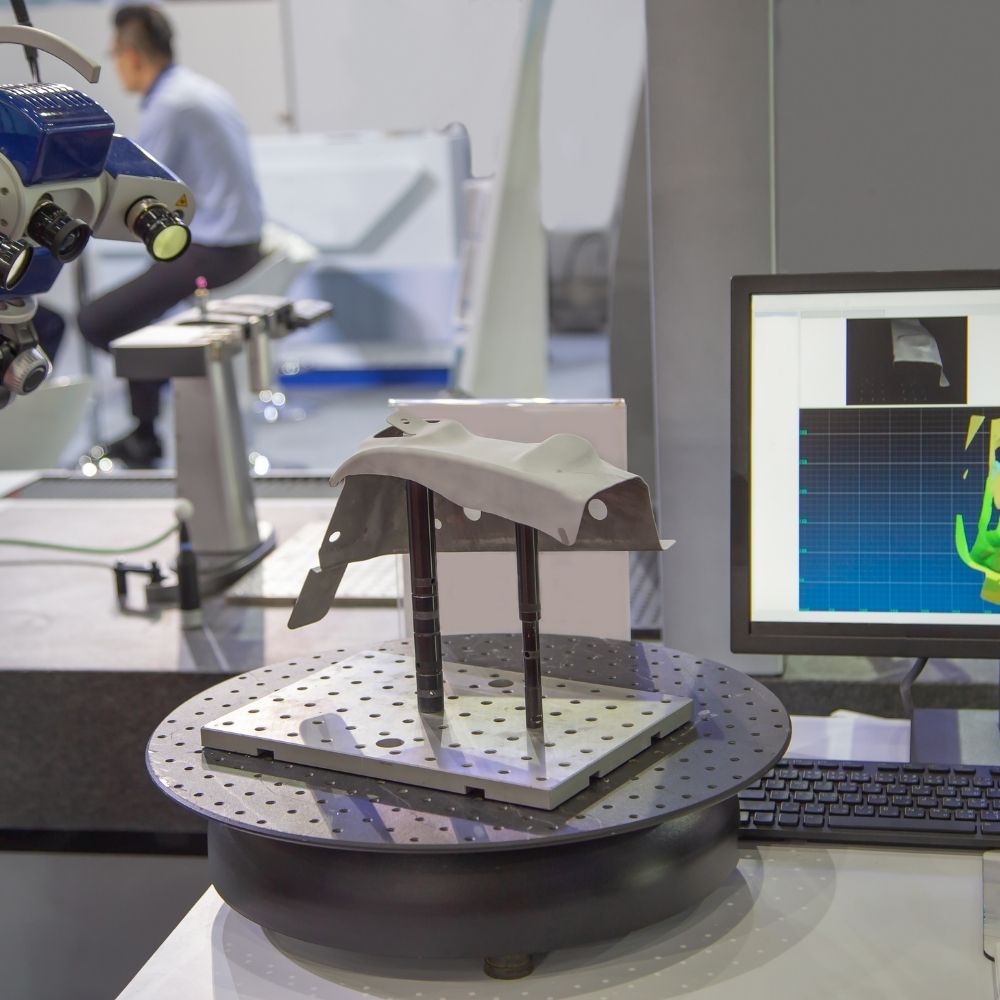

3D scanning has revolutionized many industries. It has made an impact on almost all industries, from automotive manufacturers to mining. Structured light scanners work accurately and quickly. 3D scanners will scan an object multiple times and from different angles to produce a virtual design within seconds. These are a few reasons to use 3D scanning in manufacturing.

Faster Prototype Process

Putting together an accurate prototype will often require multiple attempts. With 3D structured scanning, you’ll be able to shorten this process. You may even reduce the number of prototype cycles needed during the production and design processes. A scan allows you to save data related to the scan, measure cross-sections, and identify areas that need help. Then, when you have to scan a new prototype, comparing the two will be easy.

Save Time in Design Stage

Imagine you need to create a new part based on a pre-existing design. Reverse engineering is simpler, and you can easily conquer this task with structured light 3D scanning. The scanner can provide precise measurements of where the new piece must fit because it can see into every nook and cranny.

The scanners also save time when you need to alter a current piece. A scanner can work faster and be more accurate than hand-drawn dimensions.

Able To Remanufacture Parts Without CAD

CAD, or computer-aided design, hasn’t always been around, so sometimes you have to remanufacture a part that originated before CAD was around. 3D scanning makes this process possible. You have to scan the old piece and use the reverse engineer software to design a CAD model. You’ll then use the scanner to compare the two and check for accuracy.

Compare Projects To Constructed Products

Another reason to use 3D scanning in manufacturing is to compare as-designed projects with the end product, guaranteeing that the original design was successful. Comparing plans is more than quality control; rather, it ensures that the produced product will fit as needed.

Cast Steel Products offer 3D scanning and reverse engineering, along with other products and services. We are a mill liner manufacturerthat presents quality designs optimized for each unique application. Visit our website today!