Manufacturers from many different industries prefer to use investment casting as their preferred casting method. Mining, aerospace, and even healthcare uses this method because it creates intricate pieces with extreme accuracy.

Learn more about the benefits of investment casting in manufacturing!

What is Investment Casting?

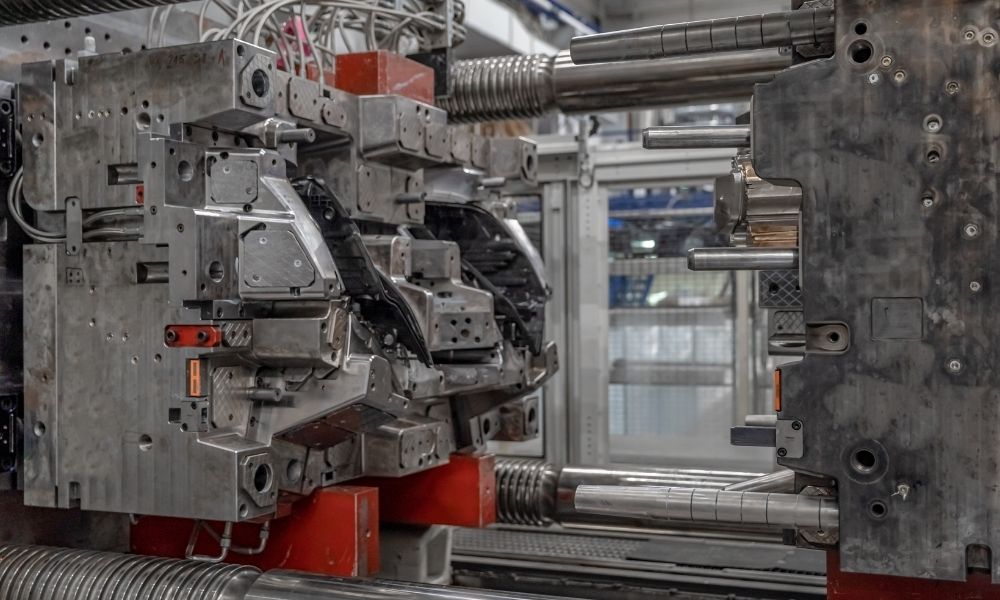

Investment casting produces intricate components while maintaining sustainability. It does this by reducing waste, energy, and follow-up machining. Design engineers prefer investment casting due to its ability to create precise parts.

Low-Tooling Costs

Investment casting reuses the same molds, and these molds can last forever. Thanks to the sustainability of the molds, choosing investment casting over other methods like die or high-gravity casting means you’ll have lower tooling costs.

Rapid Prototyping

Do you need your product to market quickly? Investment casting can create rapid prototyping, delivering your products faster than other casting techniques.

Design Versatility

If you need a mill liner or another application that requires intricate design, investment casting can create complex elements such as:

- Thin-wall segments

- Intricate passageways

- Logos

- Names and numbers

- Tight tolerances

- Smooth surfaces

Alloy Selection

You can also choose between several different alloy materials such as aluminum, copper, or ferrous. Typically, some of these materials are difficult to machine or process inexpensively. Investment casting can create complex designs with machining capability at a lower cost than other casting methods.

Applications

Because investment casting uses various metal alloys such as bronze, steel, and nickel, industries use it in many different applications. Industrial components like mill liners, turbine blades, and gears come from this casting method as well as everyday supplies such as jewelry, medical equipment, and golf clubs.

Consistency

Since foundries can reuse investment casting materials, they can repeat designs easily to create inexpensive repeat runs that match the consistency of the original piece.

The benefits of investment casting in manufacturing include sustainability and the complexity to ensure your steel mill liners have the necessary intricate designs to protect your machinery. Learn more about the casting process by exploring the blogs at Cast Steel Products.